Grasping Supply Chain Visibility

When we talk about supply chain visibility, we’re diving into the ability to keep tabs on products, data, and financial movements throughout the entire supply chain. True visibility isn’t just a buzzword; it involves crucial elements like collecting and analyzing data, real-time monitoring, and promoting transparency among everyone involved. With technology advancing at lightning speed, the importance of solid supply chain management practices has never been clearer. Businesses are now able to tap into insights that can truly boost their operational efficiency.

A big piece of the puzzle for achieving visibility is effective data collection. Companies need to pull together information from all corners of their supply chain—think suppliers, manufacturers, distributors, and retailers. This data can cover everything from inventory levels to shipment statuses and production timelines. By focusing on gathering the right data, businesses can make smarter decisions, quickly adapting to new trends or unexpected hiccups.

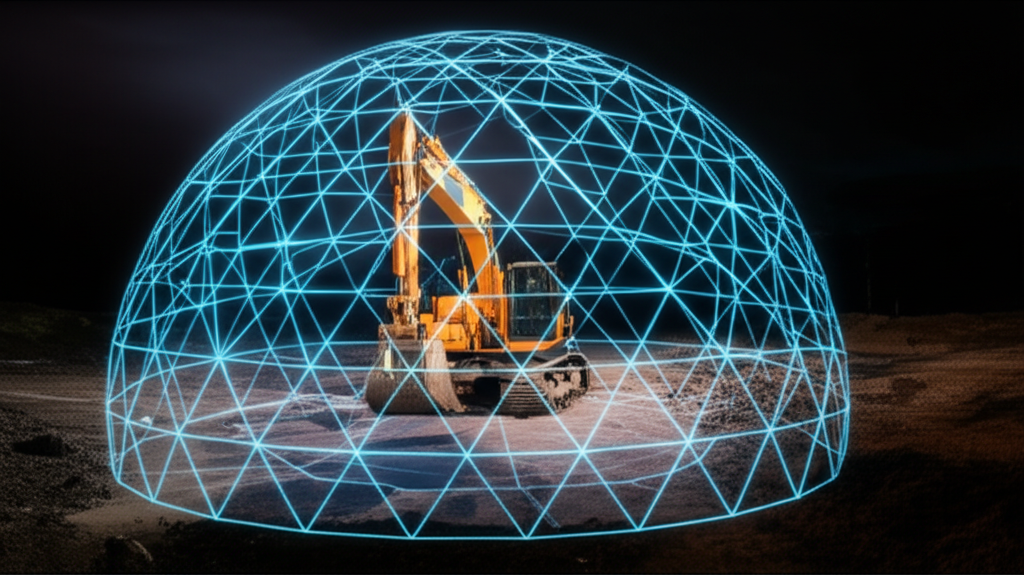

Real-time monitoring is also a game changer. With technologies like the Protrack GPS platform, companies can keep an eye on their assets as they move through the supply chain. This means not only tracking shipments but also being able to react immediately to issues like delays or damages. Implementing real-time tracking helps organizations streamline their operations and reduce the risks that come from blind spots in their supply chains.

Moreover, fostering transparency among all supply chain partners is key. A clear view of the entire supply chain encourages collaboration and trust, allowing partners to easily share critical information. When everyone has insight into the process, it leads to better strategic decision-making and faster responses, ultimately boosting efficiency and customer satisfaction. In short, true visibility in supply chain management is essential for optimizing performance and is vital for any modern business.

Boosting Efficiency and Cutting Costs

True visibility in supply chain management is a powerhouse when it comes to enhancing operational efficiency and trimming costs. By harnessing advanced tools like the Protrack GPS platform, businesses can access real-time data that dramatically improves inventory management, order fulfillment, and logistics processes. This wealth of information allows organizations to keep a closer eye on their supply chains, leading to quicker, more informed decision-making.

Take, for example, a company that integrates a Protrack GPS tracker into its operations. They can monitor their assets throughout the shipping journey, which not only aids in precise inventory management but also helps avoid overstocking and stockouts. By having real-time visibility into inventory, businesses can better predict demand, ensuring they meet customer needs without racking up unnecessary holding costs. This insight is crucial for fine-tuning supply chain processes.

Furthermore, true visibility helps identify bottlenecks and inefficiencies lurking in the supply chain. Companies using visibility tools can spot delays in order fulfillment or logistics, enabling them to act quickly. For instance, a well-known retail company adopted a GPS tracking solution that revealed persistent delays in their deliveries. By tackling these issues head-on, they not only sped up their delivery times but also significantly cut overall operational costs. This example highlights how embracing comprehensive visibility tools can streamline processes and boost productivity.

In conclusion, enhancing visibility in supply chain management with platforms like Protrack can lead to substantial gains in efficiency and cost savings. By investing in these technologies, companies can elevate their operational performance while providing better value to their customers.

Strengthening Risk Management

In today’s shifting landscape of supply chain management, having enhanced visibility is crucial for organizations looking to anticipate and mitigate various risks. With tools like the Protrack GPS platform, businesses can leverage real-time data to gain insights that were once out of reach. Improved visibility helps companies spot potential supply disruptions, demand shifts, and compliance issues early, allowing for proactive measures instead of reactive ones.

Supply chain risks can arise from many sources—be it geopolitical issues, natural disasters, or changing consumer preferences. Advanced tracking systems let businesses closely monitor their logistics, analyzing patterns that may signal an impending risk. For example, organizations can look at historical data to predict high-demand periods and adjust their inventory accordingly to avoid running out of stock. This forward-thinking approach enhances agility and minimizes waste.

Additionally, compliance with regulations can pose significant risks. With greater visibility, firms can monitor compliance across their supply chain, tracking key performance indicators (KPIs) and ensuring all suppliers meet necessary guidelines. Proactive monitoring through digital platforms helps catch discrepancies early, reducing the risk of costly penalties or damage to reputation.

Real-world examples illustrate how businesses have successfully navigated challenges using enhanced visibility. For instance, a major retail chain employed the Protrack GPS tracker to monitor shipments in real time, allowing them to adjust their logistics strategies swiftly during unexpected disruptions. This adaptability not only protected their operations but also reinforced consumer trust in their brand. By utilizing visibility tools, organizations can craft responsive risk management plans, bolstering their resilience against challenges.

Building Stronger Supplier Relationships

True visibility in supply chain management is vital for cultivating strong relationships with suppliers. By using visibility tools and strategies, organizations can create a transparent and communicative environment. Integrating advanced systems like the Protrack GPS platform allows stakeholders to manage and track all supply chain aspects seamlessly, fostering trust and collaboration.

When companies use tools such as the Protrack GPS tracker, they gain real-time insights into their supply chain processes. With this information at their fingertips, both organizations and suppliers can work together to tackle challenges, solve problems, and innovate. When suppliers know what is expected and receive regular feedback through efficient communication channels, it leads to higher engagement and a commitment to those expectations.

Moreover, sharing data encourages a more strategic approach to managing supplier relationships. Instead of seeing suppliers merely as vendors, organizations can treat them as partners. This shift in perspective opens the door to collaborating on projects and product development. By analyzing data together, both parties can identify potential bottlenecks and devise solutions proactively, reducing delays and inefficiencies.

Plenty of successful partnerships demonstrate how true visibility can strengthen supplier relationships. Companies that prioritize transparency and frequent communication often experience not just improved satisfaction among suppliers but also enhanced performance metrics. Ultimately, leveraging visibility tools solidifies trust and creates a more agile, responsive supply chain—essential for thriving in today’s competitive marketplace.